Iron foundry basics

Practical Action

Pattern Making

Patterns, which are simply copies of the shapes of casting required are made of wood. Preferably a

hard wood is used and finished with a covering of good quality, water-resisting varnish or paint. This

helps to resist damage to the mould when withdrawing and also tends to be less affected by

moisture picked up from the moulding sand which is always damp.

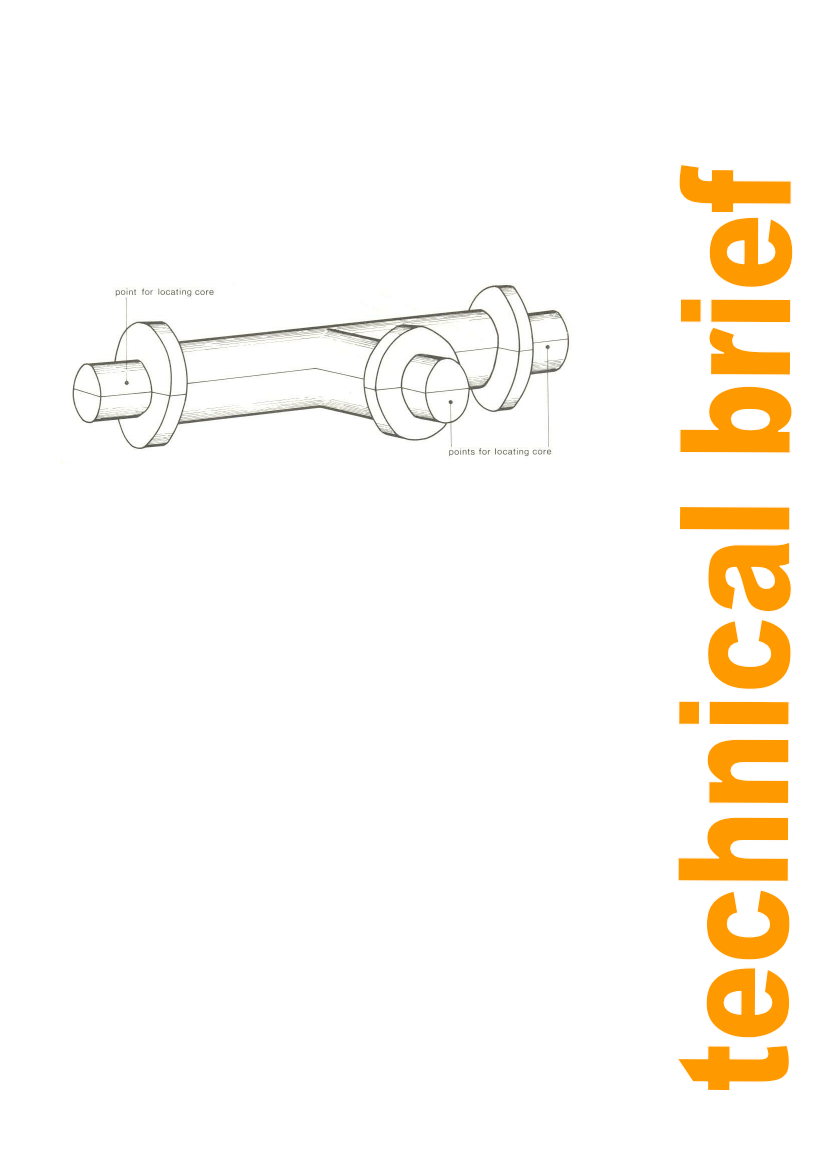

Figure 17: Split wooden pattern halves located by dowels

Patterns should be made very carefully to the required dimensions, but allowing (1 % of length)

oversize, to compensate for the shrinkage of metal as it cools.

Patterns are usually in two halves, which are correctly aligned to each other by the use of dowel

pins. More advanced patterns made of metal, cast-iron, brass, aluminium alloy, or white metal can

be used, but these are more difficult to produce, because of the accuracy required and are

therefore more costly. It is much easier and quicker to work with wood than metal, though of

course, the metal patterns are more durable (Fig. 17).

Equipment Required

Core Boxes

Wood

To requirement – made locally

Patterns

Small oven for 520°F

(270°C)

Moulding Boxes

Moulders Tools

Peg Rammer

Wood

To requirement – made locally

Metal/wood

For baking cores

Various sizes

Wood/Metal Locally Made

Flat Rammer

Wood/Metal Locally Made

Strickle (wooden

(Straight edge)

Wood

Locally Made

Vent Wire

16g wire

Purchase locally

Trowel

imported

Ex UK

Available locally

Sieve (or riddle)

3/16” mesh

imported

ex UK

Available locally

Conclusion

Readers are reminded that this profile is not intended as a technical instruction, but only as a

guide or introduction to the lower levels of the foundry industry. For those interested a list of

14